As one of the UK’s leading Hand PPE suppliers, we’re experts at knowing what safety gloves will meet and exceed the performance levels you require. But we’re more than just a safety glove supplier, we deliver advice and guidance on the risks you’re facing, and how to stay fully protected.

We also like to share our knowledge, so you’re up to date and in the know about the evolution of safety glove standards and what to consider when choosing safety gloves. And one of the most important things to understand regarding hand protection is the EN safety glove standards.

Gloves are the most used form of protective gear. Why? Because hands are the part of a worker’s body most exposed to harmful factors such as extreme temperatures, chemicals, or dangerous equipment. Gloves protect not only palms and fingers but also make objects easier to handle.

Safety gloves are an essential part of your PPE. They provide resistance to cuts, abrasions, chemicals, and tears, and specialist gloves will provide other task-specific protection. And like any other type of suitable PPE, they must meet certain standards to make them suitable for the task at hand.

The general requirement for safety gloves is EN420, which functions as a symbol of authentication for high-quality safety gloves. It's the basic standard for all types of safety gloves, covering everything from a disposable medical glove to a fully heat-resistant glove for soldering.

Gloves that meet the EN420 standard need to adhere to the following:

As well as EN420, what other safety glove standard will you need to protect your hands? This will depend on how you intend to use the gloves and the work you do. It’s important that you consider the following key factors when sourcing PPE safety gloves:

When it comes to analysing the hazards themselves, most can be grouped into one of four main categories that the gloves will need to protect against:

Each category has an EN standard that relates to the type of protection it gives. And within each glove category, the resistance is rated with a number (in brackets) to show its protective capability:

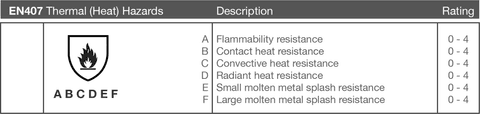

Thermal hazard protection falls into six types of resistance:

We help you find the right thermal hazard hand protection and provide expert advice on what safety gloves will work best for you. We work with manufacturers to develop the right gloves, gauntlets, and mitts, made from materials for heat resistance and thermal hazard protection.

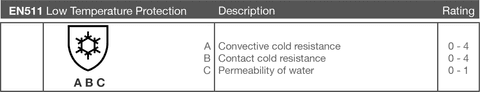

Cold hazard protection falls into three types of resistance:

Cold hazard protection can come in many types of safety glove, made from the latest in material technology. We will help you stay protected no matter where you work or how you work around extreme low temperatures and cold contact.

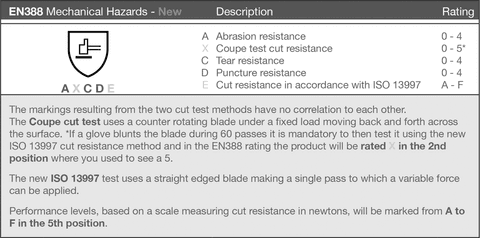

Mechanical hazard protection falls into five types of resistance. Cut resistance is rated 1-5, while all other physical performance factors are rated 1-4:

EN388 is a standard that catches many people out when it comes to which safety glove to buy. Talk to us about what your gloves will be used for, and we’ll make sure you have safety gloves that are always fit for purpose and protecting against hazards and providing the best cost-in-use.

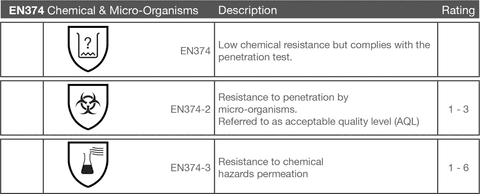

EN374 is a standard designed to test how a glove responds to chemicals and micro-organisms, and to see how waterproof they are. This essentially means testing if a liquid or micro-organism can pass through the material. EN374 is broken down into three separate standards:

EN374 – Low chemical resistance but complies with the penetration test

EN374-2 – Resistance to penetration by micro-organisms. Referred to as acceptable quality level (AQL) (1-3)

EN374-3 – Resistance to chemical permeation (1-6)

Safety gloves need to cover a wide variety of tasks and hazards and be tested against possible risks to protect your hands. Here are some of the other safety gloves standards to be aware of:

In an industry where safety gloves and PPE are needed to do a task, or where there is a risk to an employee’s health and safety, employers are responsible for:

We’re more than a supplier of PPE such as safety gloves. As a BSiF member, our expert advice and knowledge helps ensure you remain a responsible employer that looks after worker safety.

Contact us on 01202 718000 or browse our catalogue to see our: