We explain the three categories of PPE and how they cover a range of simple and complex designs.

Personal Protective Equipment (PPE) minimises the exposure to hazards that cause serious workplace injuries and illnesses. Over 2M people worldwide suffer from work-related injuries each year, which makes buying PPE one of the most important decisions you can make. PPE doesn’t reduce the risk itself, that’s why it’s at the bottom of the hierarchy of controls. But the right PPE could be the difference between life and death - that's why partnering with a trusted PPE product supplier is essential.

All working environments are full of hazards, whether you work on a railway or handle food. Employers therefore have a legal obligation to protect their workers and are responsible for completing risk assessments to determine the types of PPE needed. The PPE Regulation legal laws can be used for guidance as to what PPE is needed to match, and protect, the possible risks around the workplace.

PPE manufacturing is an enforced regulation designed to protect you and your employees from any risks to health & safety in the workplace. Manufacturers of PPE are responsible to ensure their products meet the legal requirements and quality of performance. All products that get placed on the market within the EU and EEA, must also be CE marked. And from January 2023, for items sold in the UK, they must be UKCA marked only.

The PPE legislation is a European regulation, yet it has one of the strictest enforcement requirements for PPE in the world. This accounts for the high level of compliance with European PPE regulations. PPE regulation came into force on the 21st of April 2018, which replaced the PPE directive which had been in place since 1995.

Everyone including manufacturer, distributer, issuer, and end user, must comply with the regulations. PPE regulations are there to ensure that manufacturers apply to the rules to protect the health & safety of the user, whether intended for use at work or home. If this is not adhered to, people and businesses could face up to 3 months in prison and/or a fine of up to £5000.

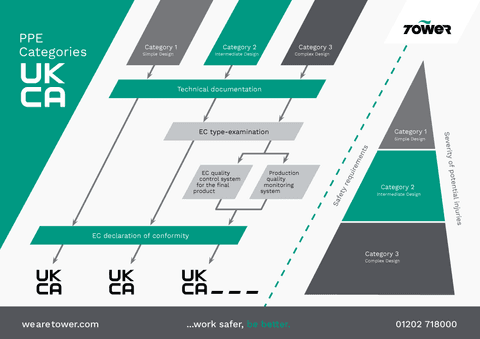

Deciding if a product is PPE is the responsibility of the manufacturer, and they may seek guidance from various sources. The PPE Directive defines PPE by splitting it into three classes. This makes certain that each piece of equipment fits the legislated standard for its specific use. This also ensures that PPE has the proper documentation and goes through the correct examinations when necessary.

Category I PPE is simple in design and simple in terms of what risk it’s protecting you from.

Includes mechanical or thermal gloves that protect against cuts, puncture, and tearing etc.

PPE that is simple in design is self-declared and then certified before being placed on the marketplace.

Does not go through testing or auditing, with the manufacturer determining what is used as PPE.

Category II covers ‘intermediate’ PPE. This is PPE that is neither complex nor simple in design.

Produced by the manufacturer, then tested at a test house and issued a certificate.

Would include most types of helmets, safety footwear, hi vis clothing, safety spectacles or FR overall.

Involvement of a notified body being compulsory, an example being EN443 products.

Covers complex PPE used to protect against hazards that can lead to death or permanent injuries.

Examples are acid resistance clothing, electric arc protective clothing, and fire protective clothing.

Any category III PPE must be designed in accordance with the EN standard they’re designed for.

Goes through a certification process and production auditing to ensure it meets requirements.

If you have any concerns of questions regarding PPE in the workplace, contact one of our expert team to discuss your requirements. Simply call 01202 718000 or fill out a contact form below.