The standard for insulating gloves made from rubber.

This standard describes manufacturing and testing processes for insulating gloves made of rubber designed to protect wearers from electrical shock and defines the minimum electrical, chemical, and physical properties of voltage-rated gloves.

ASTM D120 - Standard Specification for Insulating Gloves Made of Rubber

ASTM requires gloves to be manufactured within similar hand dimensions, plus or minus ½” per measurement. This allowance provides manufacturers with the opportunity to select a set of unique dimensions.

Two types of gloves are detailed in this standard:

Type I: non-resistant to ozone Type II: resistant to ozone

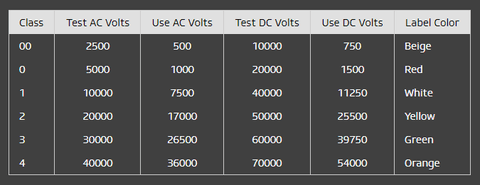

Six classes of gloves, differentiated by their electrical characteristics, are detailed in this:

Class 00, Class 0, Class 1, Class 2, Class 3, Class 4

The following tests must be performed:

AC proof testAC breakdown testAC moisture absorption/proof testDC proof testDC breakdown testOzone resistance testChemical testsTensile strengthTear resistance testPuncture resistance test

Electrical safety gloves are categorized by their capacity to provide voltage protection and to provide resistance to ozone. To select the proper level of hand protection, use the chart below to determine the maximum voltage that the wearer will be exposed to during work. Each glove class is clearly marked with the maximum use voltage on the permanent colour-coded label.

Voltage-rated gloves should always be purchased with leather protectors and a storage container.

To protect the wearer properly, a glove system consists of:

Rubber insulating gloves – classified by the level of voltage protection they provide.

Liner gloves – reduce the discomfort of insulating gloves made of rubber. Liners provide warmth in cold temperatures and absorb perspiration during work in warmer temperatures. They can have a straight cuff or knitted wrist.

Leather protector gloves – worn over insulating gloves made of rubber to protect against cuts, abrasions, and punctures.

Leather protectors:

In the ASTM standards specifying the characteristics of leather protector gloves, there are regulations concerning how much of the rubber glove can be exposed at the top (i.e., near the cuff.) Due to this, certain leather protector gloves are used with specific classes of rubber gloves according to their length (see below). Note: these protectors are not interchangeable with different classes of rubber gloves.

Class 00 & 0 must have no less than a ½” gap between the top of the glove and the top of the leather protector. Class 1 must have no less than a 1” gap between the top of the glove and the top of the leather protector. Class 2 must have no less than a 2” gap between the top of the glove and the top of the leather protector. Class 3 must have no less than a 3” gap between the top of the glove and the top of the leather protector. Class 4 must have no less than a 4” gap between the top of the glove and the top of the leather protector.

Marking requirements on the label:

Size, Manufacturer, ANSI/ASTM standard, Country of origin, Class, Type, Max Use Volt AC/ ColorCuff design, Length

Gloves should be worn within 12 months of their test date to ensure full protection against specified hazards. Unused gloves may be retested and, pending recertification, should be used within 12 months.