We’ve been shining the light on electric vehicle PPE and inviting people to Talk EV with us. It’s an important topic, with one-sixth of all new UK car sales now being an EV*. That’s why we’re asking: what’s your risk assessment when it comes to EV? How is it different to regular vehicles?

The recovery issues and risks that are unique to electric vehicles might surprise you. That’s why it’s a hot topic for any breakdown provider and their patrols.

But what can cause an electric vehicle to break down in the first place?

We've been busy behind the scenes working with leading professionals in the EV sector to build our complete EV safety series, and part three will be released VERY soon!

Now that EV are commonplace on the roads, it’s becoming clear that despite its eco-friendly engine they are not without their problems. The first thing that might come to mind is simply running out of battery or feeling ‘range anxiety’. But it turns out an empty battery is not the biggest issue.

According to LV Britannia Rescue, only 11% of EV callouts deal with running out of battery. Instead, it’s the 36% of callouts for wheels and tyre problems that are becoming a bigger issue. This is over twice the amount that makes up tyre call outs for petrol and diesel vehicles.

Why is this?

Because the excess weight of the car’s batteries makes it 50% heavier than a traditional car which puts more stress on the tyres. To make things worse, most manufacturers no longer fit a spare wheel as standard. It’s no wonder that EV drivers need assistance for tyres.

What issues do roadside recovery and breakdown providers face when an EV does breakdown?

It can often be a big problem to tow an EV vehicle, as they are often automatic and 4-wheel drive, so can be easily damaged. The Nissan Leaf for example, should not be towed at all with the front wheels on the ground, or four wheels on the ground, as this may cause damage to the motor.

But it turns out that two of our biggest automotive customers have found a solution.

After being the first to launch an all-electric break-down vehicle, the RAC helped solve the difficulties of towing EV with their All Wheels Up rapid deployment trailer (RDT).

The purpose-built kit extends out of the RAC patrol van to securely lift all four wheels of the broken-down EV off the ground, which eliminates all risks of damage typically caused by towing. See it in action below...

The AA also have a solution designed by AA Chief Engineer Steve Ives called the ‘freewheeling hub’. The idea is that two hubs are attached to the outside of the EV wheels, so that they can raise the two front wheels and pull the car along on the freewheeling hub instead of the wheels.

Some breakdown providers use on-board chargers run off a diesel engine. This isn’t good for the environment and can take a long time. The freewheeling hub is a much safer and environmentally friendly solution and gets a much more positive response from AA customers.

The AA, a Tower automotive customer, has partnered with the Institute of the Motor Industry (IMI) to upskill and train 2,000 EV patrols. AA patrols are already trained to IMI Level 1 equivalent, and now the AA wants to train them to become IMI Level 2 equivalent by the end of 2022.

Patrols based in areas with a high rate of EV ownership, will be upskilled to IMI Level 3 equivalent standard during 2022, with more to be trained in 2023. Level 3 will ensure the patrols follow best safety practices on EV, including high voltage components or systems to repair EVs at the roadside.

According to the IMI, only 6.5% of the UK automotive aftermarket workforce is EV qualified. That’s why AA training will continue for years to come. By offering CPD and training their highly skilled patrols in gold standard EV qualifications, AA can safely repair electric vehicles at the roadside.

As EV is still a growing market, patrol workers might not know the full situation or the dangers they face when called out. The inherent electrical dangers of working on EV are also exacerbated by the additional factors of being outdoors in potentially bad weather and dangerous conditions.

If insufficient protective equipment is worn, this could put the health of the worker at extreme risk. Certain types of PPE are mandatory regardless of the vehicle type, such as high visibility clothing. But with EV, there also needs to be protection in place against voltage.

In the unlikely but dangerous event of an arc flash, the protection of hands, head, and body will keep the worker safe. All the elements of protective equipment also allow the worker to perform at their best and be layered correctly in a compatible way to minimise risk.

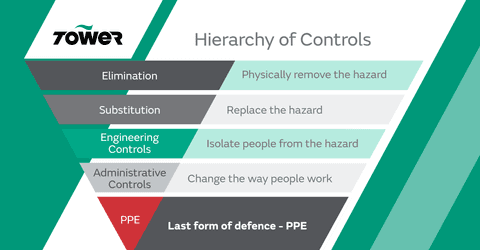

The hierarchy of risk helps you understand how to approach PPE and why it should always be the last resort. Only after all other controllable elements are dealt with should you use PPE to protect people. But once you have eliminated everything else, what PPE should you be considering?

We like to help people create a head-to-toe PPE solution. And when it comes to EV safety, you should be considering protecting your face, hands, body, and feet. This can include safety gloves, face shields, resistant clothing, and safety footwear.

Although there is currently no consensus on exactly what PPE you should be wearing to ensure you stay safe, we can still talk through what is available. We can also share best practices from other customers, to help you understand how other companies deal with risk.

Check out our FREE infographic to read a collection of EV quotes from experts in roadside recovery?

* Express.co.uk

What the experts say

We've been busy behind the scenes working with leading professionals in the EV sector to build our complete EV safety series. Bursting with industry news, eye-opening interviews, safety advice and FREE infographics, part three will be released VERY soon!

To be notified as soon as we release it, please fill in the contact form below...